Hydraulics: advanced solutions for Industrial Automation

Hydraulics represents one of the most reliable and powerful technologies in the landscape of modern industrial automation.

This branch of mechanical engineering is based on the transmission of energy through pressurized fluids, mainly mineral or synthetic oils, to generate controlled force and motion.

A&T Fluid Solutions brings together over 35 years of experience in the design and production of high-quality hydraulic components, offering complete solutions ranging from cylinders to power units, from valves to customized integrated systems.

What Is Meant by Hydraulics and What It Is Used For

Hydraulics is based on Pascal’s principle, according to which pressure applied to an incompressible fluid in a closed container is transmitted uniformly in all directions.

This physical principle makes it possible to multiply applied forces and transmit them accurately even over long distances, enabling the control of heavy loads with high precision.

Hydraulic technology is used wherever it is necessary to generate high forces in confined spaces, while ensuring precision in positioning and execution speed.

Compared to other energy transmission systems, hydraulics offers an exceptional power-to-weight ratio and a level of force modulation that makes it indispensable in many industrial applications.

How Hydraulics Works

A complete hydraulic system consists of several components working together to ensure optimal system operation.

Each element performs a specific function within the hydraulic circuit, contributing to the generation, control, and distribution of hydraulic energy.

Essential Components of Hydraulic Systems

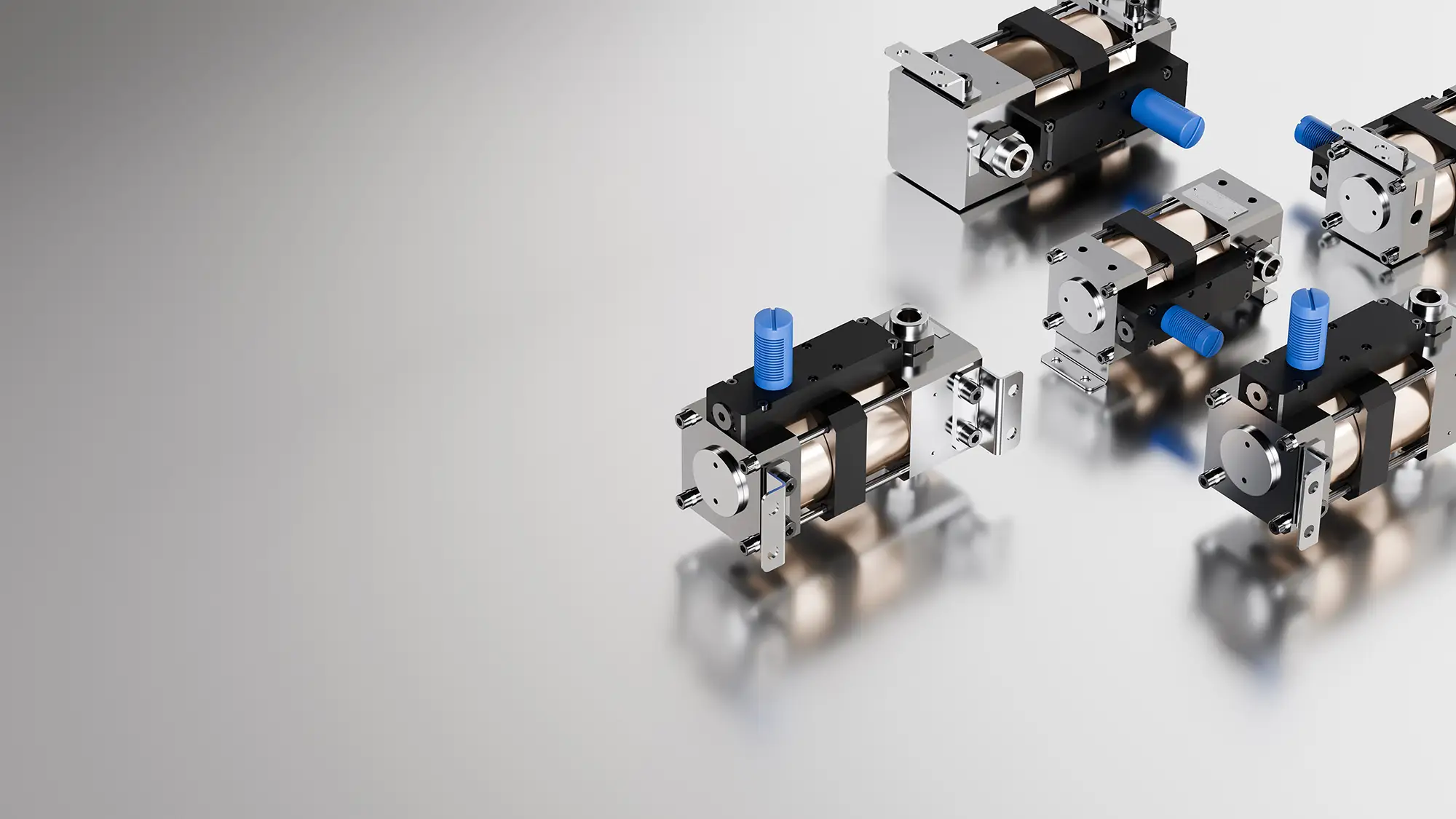

- Pumps: they represent the beating heart of every system. These devices convert mechanical energy from an electric or internal combustion motor into hydraulic energy, creating the fluid flow required for system operation. Pumps can be fixed or variable displacement, depending on application requirements, and are available in different types: gear pumps, vane pumps, axial piston pumps, or radial piston pumps. The choice of the appropriate pump depends on the pressure, flow rate, and usage characteristics required by the application.

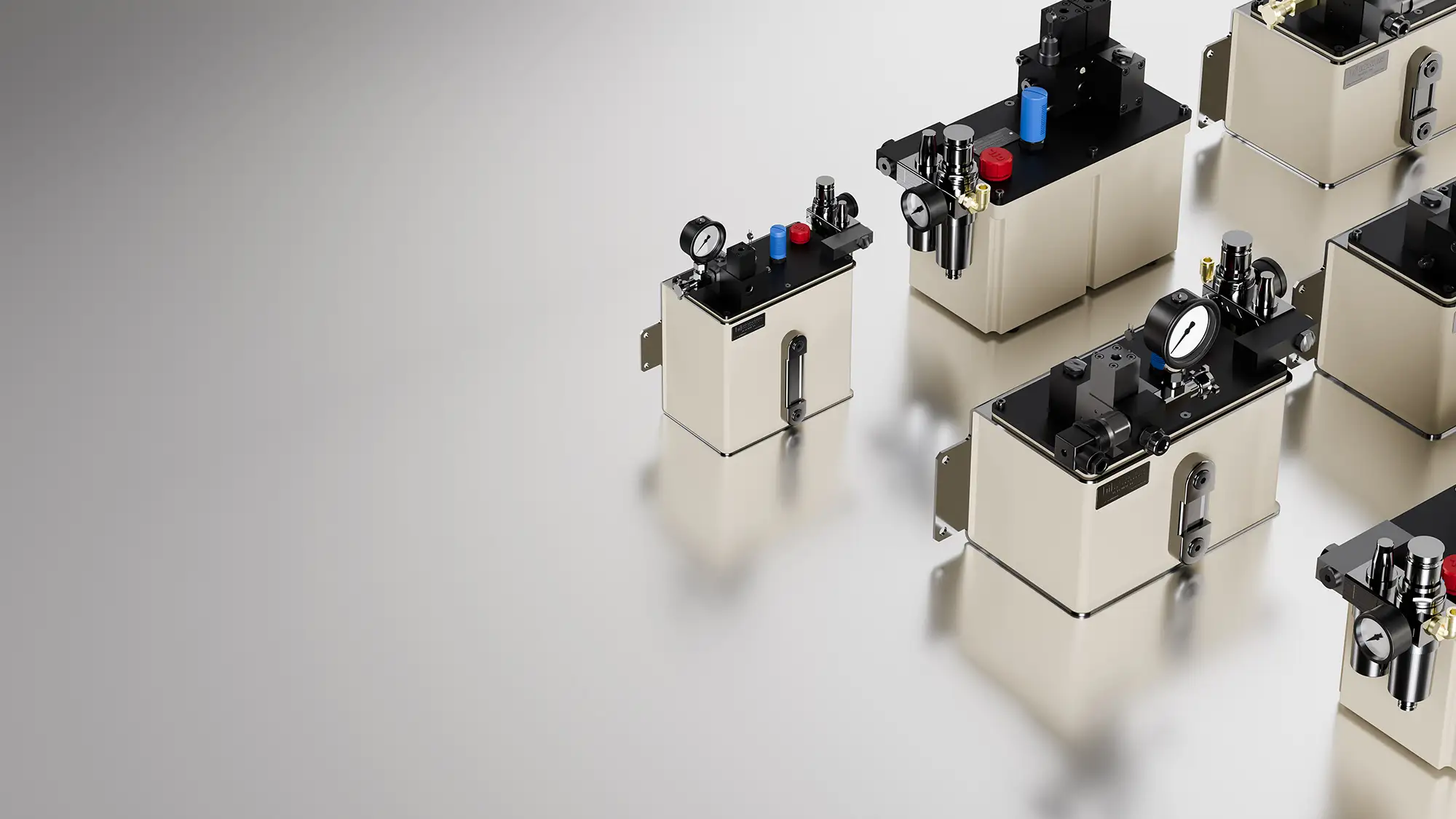

- Power units: they constitute the system’s power unit, integrating the pump, electric motor, oil tank, filters, and control and safety devices into a compact assembly. Power units represent the functional core of the system and can be custom-designed to meet specific pressure, flow, and duty cycle requirements. A&T Fluid Solutions develops customized power units that optimize energy efficiency and ensure long-term reliability.

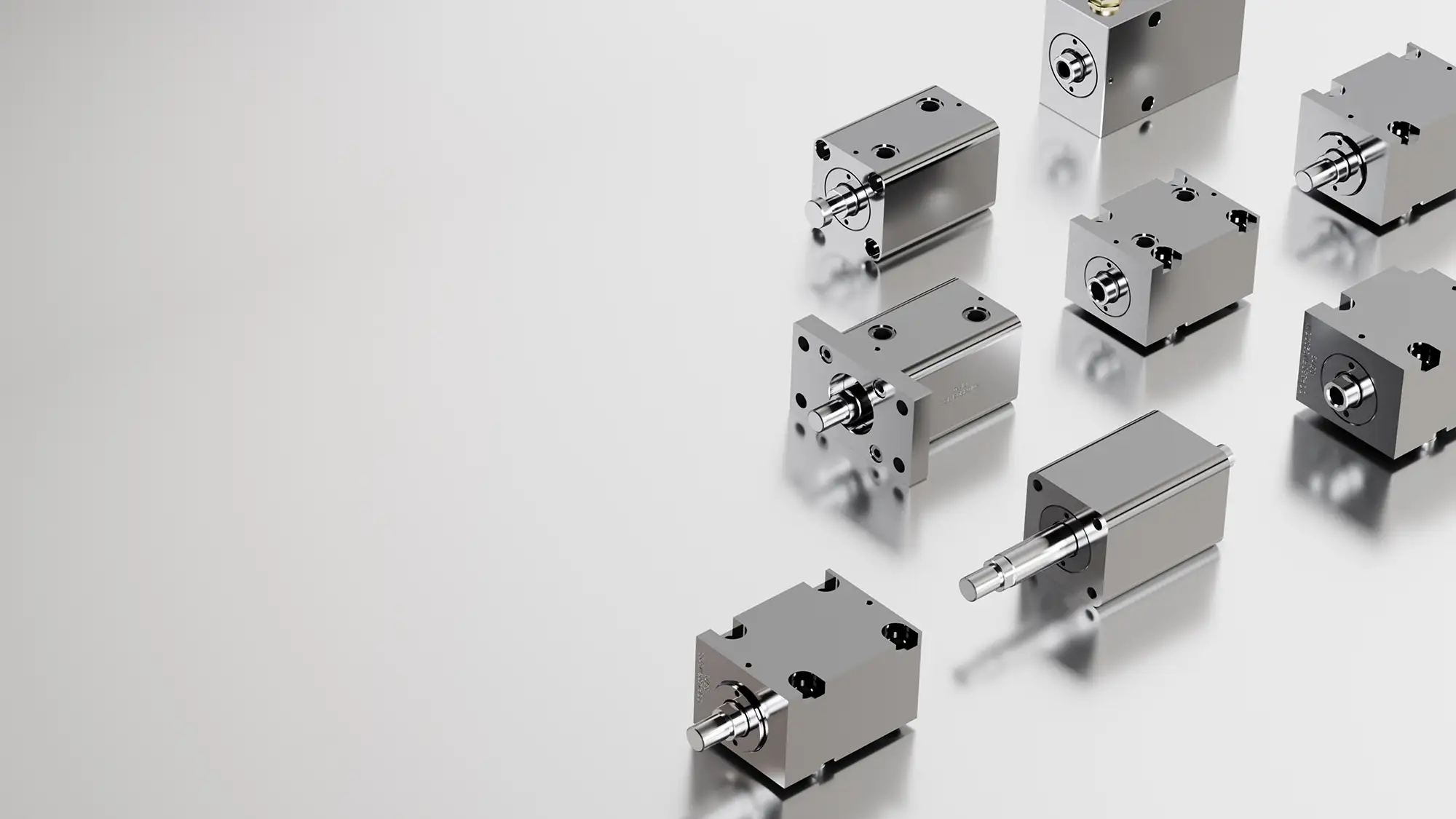

- Cylinders: these are the actuators that convert hydraulic energy into linear motion. Available in single-acting or double-acting configurations, cylinders can be standard or compact and are manufactured using materials and surface treatments designed to withstand the harshest environments. Careful cylinder design, from seal selection to machining tolerances, determines the durability and reliability of the entire system.

- Directional valves: their function is to direct the oil flow to the different users within the circuit. These components, also known as directional control valves, control the direction of actuator movement and can be manually, mechanically, electrically, or pneumatically actuated. Modern valves offer high performance in terms of flow rate and switching speed, making them essential for applications requiring speed and precision.

- Valves: they form a broad and diverse family of components that regulate fluid pressure, flow, and direction. Pressure valves protect the system from dangerous overpressure, flow control valves regulate actuator speed, while check and load-holding valves maintain achieved positions even in the absence of power. Proper valve selection and calibration are essential to ensure safety and operational efficiency.

- Spare parts: the availability of original spare parts ensures the operational continuity of systems. Seals, filters, sensors, and other wear components must be replaced periodically according to preventive maintenance schedules. A&T Fluid Solutions guarantees timely supply of certified spare parts, supporting customers in optimal maintenance management.

The Hydraulic Circuit and Technical Symbols

Understanding hydraulic diagrams is essential for correctly designing, installing, and maintaining systems. Standardized hydraulic symbols under ISO 1219 use graphical symbols to represent each circuit component, facilitating technical communication among designers, installers, and maintenance technicians.

A typical hydraulic circuit includes:

- a supply circuit (pump and tank),

- a distribution circuit (valves and piping),

- a utilization circuit (cylinders and hydraulic motors),

- and a return circuit.

Careful circuit design, taking into account pressure losses, pressure peaks, and cooling requirements, determines overall system efficiency.

Advantages of Hydraulics in Industrial Automation

The adoption of hydraulic systems offers numerous competitive advantages that explain their widespread use in the manufacturing industry.

The ability to generate extremely high forces in limited spaces is the first and most evident benefit: a compact hydraulic cylinder can lift loads of tens of tons with millimetric precision.

The modularity of hydraulic systems allows the configuration of custom-built installations, integrating standard components with customized solutions developed for specific applications.

This design flexibility, combined with the ability to finely adjust speeds and forces, makes hydraulics suitable for a wide range of production processes.

Operational reliability is another significant strength. Properly designed and maintained hydraulic systems ensure continuous duty cycles with minimal downtime.

The inherent robustness of components and their ability to operate in harsh environmental conditions (extreme temperatures, vibrations, dust) make them ideal for demanding industrial environments.

Energy efficiency, when the system is optimized, helps reduce electrical consumption while still delivering high mechanical power.

Modern hydraulic power units integrate advanced control technologies that adapt output power to actual process requirements, reducing waste and operating costs.

Application Sectors and Industrial Solutions

Hydraulics is used across a wide range of industrial sectors.

In the machine tool sector, hydraulic systems operate clamping devices, presses, bending machines, and machining centers, ensuring the precision required for high-quality mechanical machining. Hydraulic clamping cylinders, in particular, guarantee secure workpiece holding during milling and turning operations.

The steel and metallurgical industry relies heavily on hydraulics to operate rolling mills, forging presses, and material handling systems. The forces involved in these production processes require high-power hydraulic systems designed for continuous operation with high reliability.

In the earthmoving machinery and construction equipment sector, hydraulics enables the control of excavator arms, wheel loaders, cranes, and aerial platforms. Robustness and the ability to operate in dusty and humid environments make these systems indispensable for mobile applications.

Modern industrial automation integrates hydraulics and pneumatics to take advantage of the specific benefits of each technology. While pneumatics excels in high-speed applications with limited forces, hydraulics meets requirements for high power and precise control.

Specialized companies such as A&T Fluid Solutions support customers in selecting the optimal solution for each application.

Design and Customization

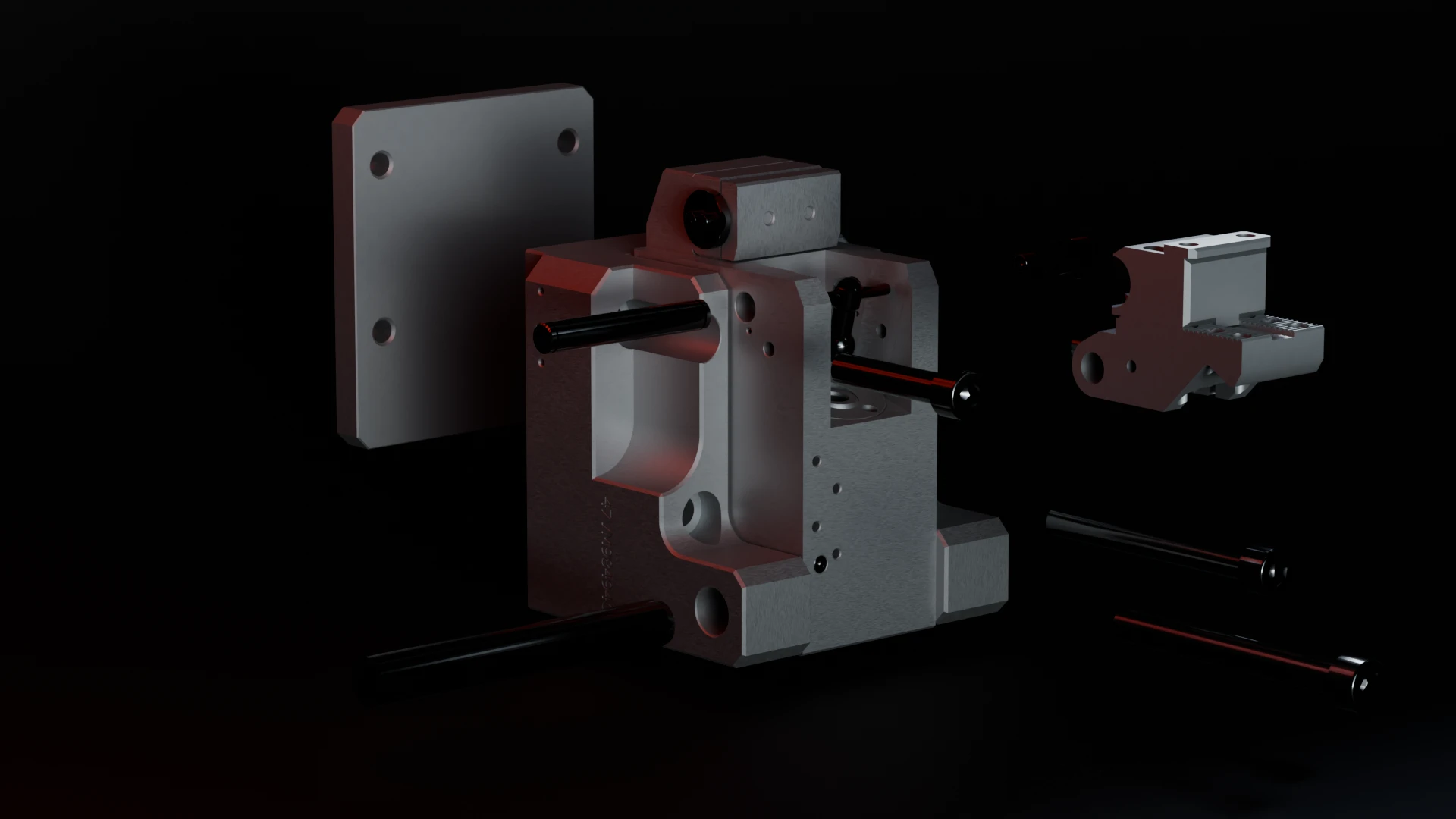

A&T Fluid Solutions stands out for its ability to design and manufacture customized hydraulic components that meet even complex technical specifications.

From understanding customer requirements to delivery of the tested finished product, every phase is managed internally with rigorous quality control.

Developing an efficient hydraulic system requires:

- the ability to analyze application requirements,

- properly size components,

- simulate the dynamic behavior of the circuit,

- and optimize operating parameters.

The experience gained over more than three decades of activity makes it possible to offer innovative solutions that anticipate market needs.

The availability of an advanced Research and Development center, combined with a modern machinery park that includes precision machining, enables the rapid prototyping of new solutions and the launch of custom production runs with competitive lead times.

This production flexibility represents added value for customers who require special components or modifications to standard products.

FAQ

When Did Hydraulics Originate?

The origins of modern hydraulics date back to the late 19th century, when industrialization required more efficient power transmission systems. Pascal’s principle had been known since the 17th century, but its industrial application developed gradually with advances in materials and manufacturing technologies. The real boom occurred in the post-war period, when industrial automation began to demand increasingly powerful and reliable actuation systems.

What Does a Hydraulic Company Do?

A company specializing in hydraulics designs, manufactures, and markets components and complete systems for power transmission using pressurized fluids. In addition to supplying standard catalog products, these companies offer customized engineering services, pre- and post-sales technical support, user training, and maintenance assistance. More structured companies have research and development departments that continuously work on product innovation.

When Is Hydraulics Used?

Hydraulics is used when it is necessary to generate high forces in confined spaces, control movements precisely even under load, ensure operational reliability in harsh environments, or finely modulate speeds and accelerations. It is the preferred choice for industrial presses, earthmoving machinery, lifting systems, steelmaking equipment, machine tools, and wherever an optimal power-to-size ratio is required.

What Is the Difference Between Pneumatics and Hydraulics?

Pneumatics uses compressed air as the working fluid, while hydraulics uses mineral or synthetic oils. Air is compressible, making pneumatic systems better suited to fast applications with moderate forces and without high positioning accuracy requirements. Oil is incompressible, allowing hydraulics to generate much higher forces with precise position control. Pneumatics is simpler and more economical for light applications, while hydraulics excels where power and precision are required.

What Is the Difference Between Hydraulics and Fluid Power?

The terms are often used interchangeably in industrial contexts. Technically, “fluid power” refers generally to systems that use fluids to transmit energy, while “hydraulics” specifically indicates the use of oils as the working fluid. In practice, within the industrial automation sector, hydraulics is the preferred term to describe power transmission systems using pressurized oils, distinguishing them from systems that use water or other fluids.

What Is Hydraulic Engineering?

Hydraulic engineering is the technical and scientific discipline concerned with the study, design, construction, and optimization of power transmission systems using pressurized fluids. It integrates knowledge of fluid mechanics, thermodynamics, materials science, electronics, and automatic controls. Hydraulic engineers analyze application requirements, size circuits and components, simulate system behavior, and develop innovative solutions to improve efficiency, reliability, and performance of industrial systems.

Special products

tailor-made

A&T stands out for its ability to offer custom-made products, designed to meet every specific need in the field of pneumatic and hydraulic solutions. We guarantee precision, quality, and innovation in every detail to ensure maximum efficiency and reliability.